Material of the XXI century

It may seem strange to someone, but foam glass is not a fantastic hyperbole or a "freshly baked" idea, but a number of decades already known material. Moreover, many scientists have long referred to it as "the insulating material of the 21st century".

To develop the technology of foam glass production began in the 30s of the last century in the USSR. Even then, glass could be foamed, but it was considered a production marriage. And when the scientists finally substantiated the effectiveness and necessity of using foam glass to increase the thermal insulation, the material needed in terms of parameters and characteristics could not produce due to the technological imperfection of the equipment then available. Either qualitative foam glass was produced on experimental sites, but the price of its manufacture was incommensurable with the possibility of further mass production.

So the second half of the 20th century was spent trying to create the optimal technology for the production of foam glass, but already leading industrial countries of the world joined this race. By the end of the century the "technological race" was won by the Americans. Russia and Byelorussia, where the main developments were also carried out, due to well-known socio-economic reasons, were turned off for a sufficiently long time from the scientific and industrial competition, and of course there was no holy place. So today, most consumers of foam glass not without reason believe that his homeland is the United States.

Meanwhile, the search for optimal technology in other countries did not stop, but a high-quality foam glass, comparable to the American one, could not be obtained. Until recently. More precisely, before the appearance of the company "STES-Vladimir".

Dear search

In the 1990s, today's general director of STES-Vladimir, Mikhail Dudko, together with his colleagues worked on construction in Siberia, including in the oil industry. And the issue of providing quality insulation was more than once extremely acute in the daily practice of activities. But where was it taken? Mineralized cotton wool or glass wool, as well as any other heaters used, did not withstand the operating conditions and fell into disrepair for several years. As it turned out later, a similar situation is typical not only for Siberia, but also for most of the Russian regions.

Then Dudko and his associates decided to tackle this problem, and to find, if not ideal, then close to such a thermal insulation material. And quite soon the theme of producing high-quality foam glass completely occupied their minds. And after a while for a while CJSC "STES-Vladimir" appeared, which was seriously aimed at producing competitive Russian foam glass.

As a small group of specialists managed to achieve success in just a few years, where entire research institutes and technology groups of respectable international companies passed, now you certainly will not say. Today this point is explained in "STES-Vladimir" quite simply and even somehow ordinary: it took persistence, perseverance, painstaking work and a bit of luck. The rest - either common points, or commercial secrets.

Whatever it was, in 2005 the company already placed orders for manufacturing of technological equipment necessary for the production of foam glass "Neoporm". The obtained prototypes of the material met the necessary requirements, many leading Russian scientists confirmed the high performance characteristics of foam glass, and later Rosnano confirmed the availability of innovative technology and processes at the nanoscale. So the basic goal was achieved - high-quality Russian foam glass was obtained, and the optimal technology of its manufacturing was tested in experimental conditions.

Minus losses, plus savings

What is so good, useful, effective and pragmatic (plus a lot of plus parameters) foam glass "Neoporm" produced by "STES-Vladimir"?

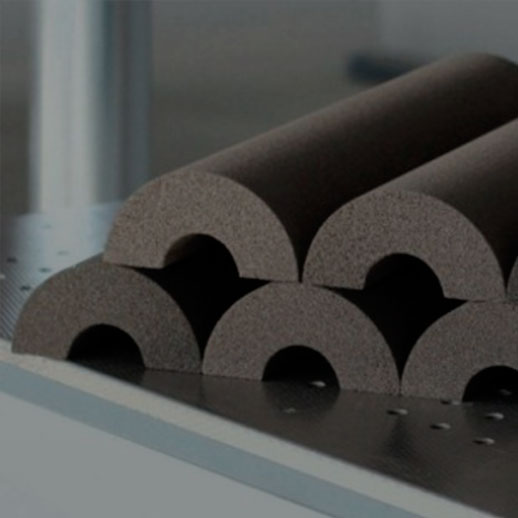

First, this material is very finely porous, which determines many of its useful performance characteristics-for example, extreme strength ("unprecedentedly high", as noted in the conclusion of the RI RAS) and reduced thermal conductivity at high temperatures. For many industries, this is almost an ideal set of qualities.

Secondly, foam glass "Neoporm" in the water does not sink and does not burn in the fire. In other words, it has absolute incombustibility and low water resistance, as well as very low thermal conductivity.

If desired (even if somewhat strange) on a standard block of foam glass produced by "STES-Vladimir", you can safely embark on a voyage, using it as an effective and reliable boat. Or hide behind the fire in the manner of an improvised shield.

However, the above examples of the use of foam glass are unlikely to gain wide popularity. But the fact that the foamed glass used as insulation does not allow water to pass through and prevents heat from flowing out is already an invaluable and unique quality for anyone who is seriously engaged in energy saving.