"The introduction of innovative technologies in the construction and production of building materials brings economic benefits and creates more comfortable conditions for human existence," the regional administration believes. For this reason, the White House strives in every possible way to fill the territory of the 33rd region with various modern manufactures, and already tries to set up existing enterprises in a new way. As a rule, all this happens in the form of eliminating a fairly substantial volume of administrative barriers related to the acquisition of land plots and the introduction of various benefits necessary for development.

In order to demonstrate the greatness and modernity of the Vladimir construction complex, on August 14 the Department of Architecture and Construction arranged for journalists an excursion to key innovative enterprises of the regional center. The achievements achieved should have made it clear that the tasks of developing housing construction are being carried out at full speed.

And the tasks are global. Governor Svetlana Orlova has repeatedly stated in her speeches that by 2020, the volume of housing commissioning should be at least one million "squares" per year. Now this figure is still more modest: construction companies have to build about 530 thousand square meters.

Priority direction of the White House considers the construction of economy-class housing, the unit cost of which will be no more than 30 thousand rubles. This should be facilitated, for example, by the participation of developers in the federal program "Housing for the Russian family", which implies a partial compensation for the costs of building facilities from budgets of different levels.

But the main emphasis in the implementation of the priority area is on innovation. Thus, the Vladimir factory of reinforced concrete structures has now mastered the technology of building houses from a prefabricated monolithic frame. According to the representatives of the VZZHBI, this method allows not only to shorten construction time, but also to work practically in any weather conditions. In addition, production volumes reach about 360 cubic meters of concrete products per day.

True, it turns out that the products of the Vladimir factory are not needed by our builders. According to QMS-technology, only one house was erected in Vladimir - on Sacco and Vanzetti streets, another house is being built in Murom. Most of the columns and bolts are delivered to Moscow and Nizhny Novgorod.

Another problem is the lack of personnel. Training of technologists in the region is not carried out now, therefore, young specialists are sorely lacking. The technical director of the plant noted that this problem is relevant for the industry as a whole: there are only four explanatory technologists in the whole country. At the same time, the salaries offered to specialists of this type at the VZZHBI are about 45 thousand rubles.

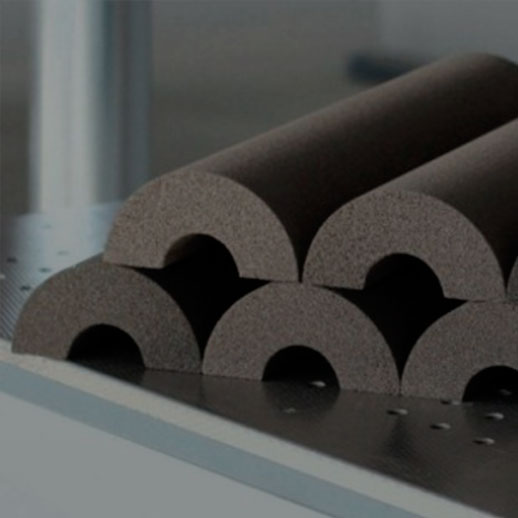

However, economy-class housing should be treated with little blood, not only for builders, but for the residents themselves. Open during the May economic forum, the plant for the production of foam glass "STES-Vladimir" offers its material as a universal thermal insulation, which can be used both for roof installation and for wall construction. According to the calculations of the first deputy director of the plant, Andrei Zinoviev, the rent in a house erected with the use of foam glass will be about one thousand rubles a month. Such a fantastic figure is achieved due to significant savings in all types of energy. By the way, the company is already going to erect such an experimental structure in 2015, and by its own efforts. However, the site on which such a house will appear is not yet defined - there are certain obstacles, which Zinoviev did not spread.

However, such an easy and wear-resistant material is too expensive for local builders to use it in their work - about 22 thousand rubles per cubic meter. Nevertheless, "STES" expects to repel the funds invested in development for 8 years. And the volume of investments, for a second, amounted to 5.6 billion rubles. By the way, at the moment the plant works in the starting-up and adjustment mode, and the first products will not enter the market before November of the current year.

As a result, it turns out that the potential of the regional enterprises still exists, but it is not being realized at full capacity. So, to fulfill the priority tasks, it is necessary not only to oblige the builders to involve the Vladimir producers, but also to radically change the attitude towards the process: to reduce the number of administrative barriers, to organize training and so on. Only after that you can already think about reducing the cost of square meters.